How to choose the coating amount of medicinal aluminum foil?

- Categories:News

- Author:吉瑞尔

- Origin:http://www.jerelpack.com/

- Time of issue:2021-12-16

- Views:384

(Summary description)How to choose the coating amount of medicinal aluminum foil?

When domestic and foreign customers are purchasing pharmaceutical PTP aluminum foil, our account manager will ask about the amount of coating required in addition to the normal quantity, specification, printing and other common problems. So what is the coating amount? What effect does it have on the use of medicinal aluminum foil? Let us find out together.

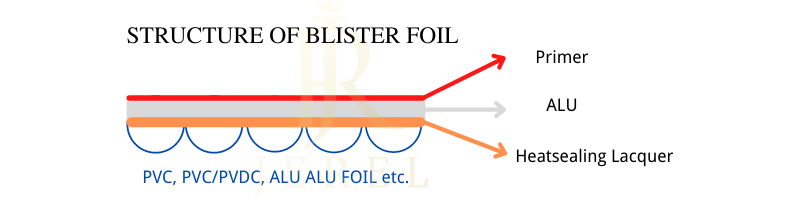

First of all, we need to know what the coating amount specifically refers to, starting from the structure of the aluminum foil. Pharmaceutical PTP aluminum foil is a coating material, and its structure is protective agent (pre-coating agent)/aluminum foil/heat sealant. Among them, the heat sealant is for bonding to hard sheets such as polyvinyl chloride (PVC), polyvinylidene chloride (PVCD), and cold-stamped aluminum. Our coating amount refers to the amount of heat sealant.

For heat sealant, our description unit is GSM (grams per square meter). According to the national standard YBB, the coating amount of the heat sealant should be between 3-5 GSM. For European and American countries, 6-8GSM is the coating amount of medicinal aluminum foil produced in accordance with European standards.

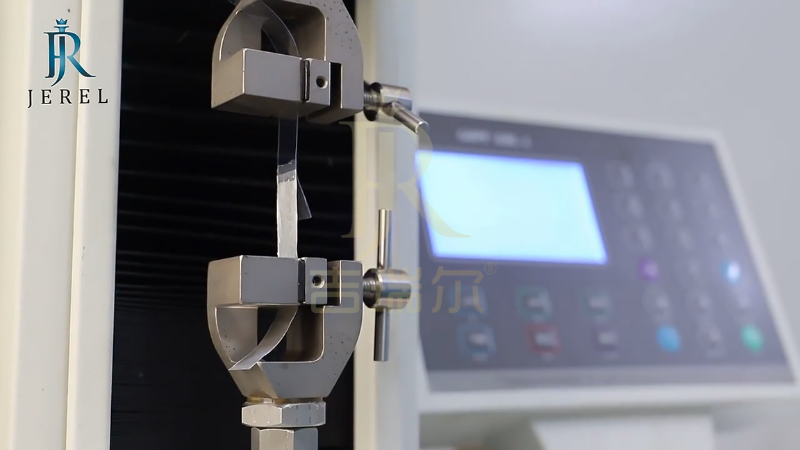

What is the difference between different coating amounts? The amount of coating has a very close relationship with one of our testing indicators-tensile strength. In the national standard, we use tensile strength to detect the adhesion between medical aluminum foil and PVC. The minimum standard is 7N/15mm (PVC), 6N/15mm (PVDC). Such data can generally be achieved with aluminum foil with a coating amount of 3-4 GSM. As for the high coating volume products of the European standard, according to our own laboratory data, a 6gsm coating sample can reach a tensile strength of 9N/15mm (PVC). The higher the heat-sealing strength of the blister package, the better the sealing effect of the medicine, which can prevent the gas from entering the blister from the poorly-sealed place to cause the deliquescence and oxidation of the medicine.

In terms of price, the higher the amount of coating, the higher the price of the product. Therefore, the best way is to combine the characteristics and cost factors of the packaged medicine to make a selection. If you still don’t know how to choose, you can also contact us to provide you with professional packaging advice and products. Ji Ruier pharmaceutical packaging, focusing on pharmaceutical aluminum foil packaging materials for 20 years.

How to choose the coating amount of medicinal aluminum foil?

(Summary description)How to choose the coating amount of medicinal aluminum foil?

When domestic and foreign customers are purchasing pharmaceutical PTP aluminum foil, our account manager will ask about the amount of coating required in addition to the normal quantity, specification, printing and other common problems. So what is the coating amount? What effect does it have on the use of medicinal aluminum foil? Let us find out together.

First of all, we need to know what the coating amount specifically refers to, starting from the structure of the aluminum foil. Pharmaceutical PTP aluminum foil is a coating material, and its structure is protective agent (pre-coating agent)/aluminum foil/heat sealant. Among them, the heat sealant is for bonding to hard sheets such as polyvinyl chloride (PVC), polyvinylidene chloride (PVCD), and cold-stamped aluminum. Our coating amount refers to the amount of heat sealant.

For heat sealant, our description unit is GSM (grams per square meter). According to the national standard YBB, the coating amount of the heat sealant should be between 3-5 GSM. For European and American countries, 6-8GSM is the coating amount of medicinal aluminum foil produced in accordance with European standards.

What is the difference between different coating amounts? The amount of coating has a very close relationship with one of our testing indicators-tensile strength. In the national standard, we use tensile strength to detect the adhesion between medical aluminum foil and PVC. The minimum standard is 7N/15mm (PVC), 6N/15mm (PVDC). Such data can generally be achieved with aluminum foil with a coating amount of 3-4 GSM. As for the high coating volume products of the European standard, according to our own laboratory data, a 6gsm coating sample can reach a tensile strength of 9N/15mm (PVC). The higher the heat-sealing strength of the blister package, the better the sealing effect of the medicine, which can prevent the gas from entering the blister from the poorly-sealed place to cause the deliquescence and oxidation of the medicine.

In terms of price, the higher the amount of coating, the higher the price of the product. Therefore, the best way is to combine the characteristics and cost factors of the packaged medicine to make a selection. If you still don’t know how to choose, you can also contact us to provide you with professional packaging advice and products. Ji Ruier pharmaceutical packaging, focusing on pharmaceutical aluminum foil packaging materials for 20 years.

- Categories:News

- Author:吉瑞尔

- Origin:http://www.jerelpack.com/

- Time of issue:2021-12-16

- Views:384

How to choose the coating amount of medicinal aluminum foil?

When domestic and foreign customers are purchasing pharmaceutical PTP aluminum foil, our account manager will ask about the amount of coating required in addition to the normal quantity, specification, printing and other common problems. So what is the coating amount? What effect does it have on the use of medicinal aluminum foil? Let us find out together.

First of all, we need to know what the coating amount specifically refers to, starting from the structure of the aluminum foil. Pharmaceutical PTP aluminum foil is a coating material, and its structure is protective agent (pre-coating agent)/aluminum foil/heat sealant. Among them, the heat sealant is for bonding to hard sheets such as polyvinyl chloride (PVC), polyvinylidene chloride (PVCD), and cold-stamped aluminum. Our coating amount refers to the amount of heat sealant.

For heat sealant, our description unit is GSM (grams per square meter). According to the national standard YBB, the coating amount of the heat sealant should be between 3-5 GSM. For European and American countries, 6-8GSM is the coating amount of medicinal aluminum foil produced in accordance with European standards.

What is the difference between different coating amounts? The amount of coating has a very close relationship with one of our testing indicators-tensile strength. In the national standard, we use tensile strength to detect the adhesion between medical aluminum foil and PVC. The minimum standard is 7N/15mm (PVC), 6N/15mm (PVDC). Such data can generally be achieved with aluminum foil with a coating amount of 3-4 GSM. As for the high coating volume products of the European standard, according to our own laboratory data, a 6gsm coating sample can reach a tensile strength of 9N/15mm (PVC). The higher the heat-sealing strength of the blister package, the better the sealing effect of the medicine, which can prevent the gas from entering the blister from the poorly-sealed place to cause the deliquescence and oxidation of the medicine.

In terms of price, the higher the amount of coating, the higher the price of the product. Therefore, the best way is to combine the characteristics and cost factors of the packaged medicine to make a selection. If you still don’t know how to choose, you can also contact us to provide you with professional packaging advice and products. JEREL pharmaceutical packaging, focusing on pharmaceutical aluminum foil packaging materials for 20 years.

Scan the QR code to read on your phone

Real-time News

Online Message

Ask about our products and prices, please leave your email, and we will contact you within 24 hours.

Sweep, mobile station

Electronic business card

Address

Daqiao Industrial Park, Jiangdu, Yangzhou,China

Copyright:Yangzhou Jerel Pharmaceutical New Material Co., Ltd. Powered by www.300.cn 苏ICP备13054439号-1