WHY COLD FORM FOIL POPULAR FOR PHARMA INDUSTRY?

- Categories:News

- Author:吉瑞尔

- Origin:http://www.jerelpack.com/

- Time of issue:2022-05-07

- Views:593

(Summary description)Cold-formed foils have been successfully used in pharmaceuticals, medical devices and in vitro diagnostics - point-of-care test kits for many years. The demand for cold-formed foils continues to grow and evolve as research scientists continue to create innovative solutions. Therefore, it is critical to have a good understanding of the specific requirements these foils need to meet, how to achieve the desired properties, and how requirements and material design affect the overall packaging design.

WHY COLD FORM FOIL POPULAR FOR PHARMA INDUSTRY?

(Summary description)Cold-formed foils have been successfully used in pharmaceuticals, medical devices and in vitro diagnostics - point-of-care test kits for many years. The demand for cold-formed foils continues to grow and evolve as research scientists continue to create innovative solutions. Therefore, it is critical to have a good understanding of the specific requirements these foils need to meet, how to achieve the desired properties, and how requirements and material design affect the overall packaging design.

- Categories:News

- Author:吉瑞尔

- Origin:http://www.jerelpack.com/

- Time of issue:2022-05-07

- Views:593

WHY COLD FORM FOIL POPULAR FOR PHARMA INDUSTRY?

Cold-formed foils have been successfully used in pharmaceuticals, medical devices and in vitro diagnostics - point-of-care test kits for many years. The demand for cold-formed foils continues to grow and evolve as research scientists continue to create innovative solutions. Therefore, it is critical to have a good understanding of the specific requirements these foils need to meet, how to achieve the desired properties, and how requirements and material design affect the overall packaging design.

In the early 1960s, Karl Klein developed the first machine to make a material containing aluminum foil into cavities or blisters that could hold solid drugs. Since then, the technology has been implemented in various other applications.

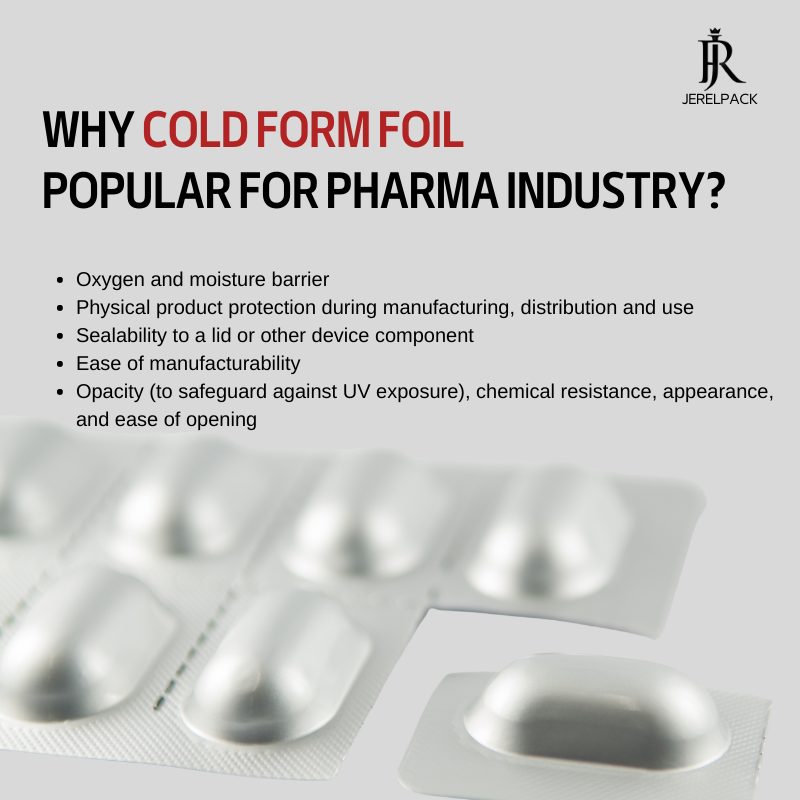

The basic benefits of cold stamping are clear, and while each specific application has its own unique requirements, in almost all cases there are requirements such as oxygen and moisture barriers, physical product protection during manufacturing, distribution and use, lids or other equipment The hermeticity of components and the ease of manufacturing factors in the package design process. Other benefits include opacity (to protect against UV exposure), chemical resistance, metallic appearance and easy opening.

In addition to these basic advantages, cold stamping, as a composite material, also has strong optimizability and adaptability. According to the characteristics of the packaged object, he can adjust the ratio of materials or replace materials to meet the needs of the contents. For example, the formation of a flexible barrier material during cold forming can result in local stretching and thickness changes of the film. The final shape and draft angle are closely related to the direct draw ratio of the material. By adjusting the thickness of the material and selecting the material with an appropriate stretch ratio, it plays a decisive role in the final presentation of the packaging.

In the environmental protection boom in recent years, themes such as "plastic ban" and "recyclable" have also promoted the development of cold-formed aluminum. The use of environmentally friendly PET, PP and other plastics instead of PVC has also become a kind of material. New trends, although the application has not yet become popular, the update and upgrade of materials has not stopped.

Scan the QR code to read on your phone

Real-time News

Online Message

Ask about our products and prices, please leave your email, and we will contact you within 24 hours.

Sweep, mobile station

Electronic business card

Address

Daqiao Industrial Park, Jiangdu, Yangzhou,China

Copyright:Yangzhou Jerel Pharmaceutical New Material Co., Ltd. Powered by www.300.cn 苏ICP备13054439号-1